M2A Series by RKI Instruments RKI Instruments

$ 1.277,00 $ 319,25

Stand Alone Explosion Proof Transmitter

Features

- Operates with or without a controller

- Direct digital readout with OLED cold temperature display

- Available gases include

◦ LEL, O2, H2S, CO, CO2, and 100% Vol CH4

◦ Toxic gases include NH3, AsH3, Cl2, ClO2, HCN, & SO2 - Infrared sensor for combustibles and CO2

- 4-20 mA & digital Modbus outputs standard

- 2 fully programmable alarm relays & fail relay

- Non-intrusive calibration via magnetic wand

- Explosion proof construction

- Patented water repellent sensor cover

- User friendly setup, push buttons & OLED menus

- Long-life sensors (2 + years typical)

Description

The RKI M2A is a state-of-the-art transmitter that can operate as an independent, stand-alone monitor or as part of an integrated system. The M2A connects with an analog or digital signal to virtually any controller, PLC, or DCS. Setup procedures are simplified with user friendly push buttons and OLED menus. It utilizes a magnetic wand technique for performing non-intrusive calibration. The M2A provides an automatic zero drift correction feature, which results in more stable readings and reduces the need for adjustments due to sensor aging.

The housing of the M2A does not need to be opened for zeroing or calibration, making it unnecessary to declassify the area for routine maintenance. It is designed so that a complete field calibration can be performed by one person. Sensor construction is rated Class I, Div. 1 Groups B, C, D for flammables, CO, H2S, O2, and CO2, and Class I, Div. 2 for all other toxics.

The transmitter provides a 4-20 mA output in addition to a Modbus digital output. It also has two levels of alarms with relays, plus a fail alarm with relay. A digital display of the gas concentration, as well as alarm and status lights, can be viewed through the front window.

The toxic sensors are electrochemical type plug-in sensors, which provide high specificity, fast response, and long life. The plug-in design allows quick replacement in the field with no tools required. Toxic sensors are designed for use in Class I, Div. 2 hazardous locations. Sensors available for NH3, AsH3, Cl2, ClO2, HCN, PH3, and SO2

The M2A represents the latest leading edge technology in sensor / transmitters today.

Specifications

Explosion Proof Class I, Div. 2 , Groups B, C, D

Toxic Gas Transmitters Class I, Div. 2M2A Toxic Transmitter Sensor Ordering Information*Partial pressure sensor for helium (He) applications. Consult factory for details.

| Combustibles |

LEL H2 Specific |

O2 Oxygen |

H2S Hydrogen Sulfide |

CO Carbon Monoxide |

CH4 Methane |

HC Hydrocarbons |

CO2 Carbon Dioxide |

|||||

| LEL | PPM | |||||||||||

| Part# | UL | 65-2640RK | 65-2647RK | 65-2641RK | 65-2643RK-05 | 65-2645RK-05 | 65-2646RK-05 | 65-2649RK-CH4

65-2658RK-CH4 |

65-2649RK-HC | 65-2660RK-02

65-2660RK-03 65-2660RK-05 65-2660RK-10 |

||

| CSA | 65-2640RK-05 | 65-2647RK-05 | 65-2641RK-05 | |||||||||

| Sensors | Catalytic | Galvanic cell | Electrochemical | Infrared | ||||||||

| Measuring Ranges | 0 – 100% LEL | 0 – 9000 ppmCH4 |

0 – 100% LEL |

0 – 25.0% Vol. | 0 – 100 ppm | 0 – 300 ppm | 0 – 100% LEL

0 – 100% Vol. |

0 – 100% LEL | -02 | 0 – 5000 ppm | ||

| -03

-05 |

0 – 5% Vol.

0 – 50% Vol. |

|||||||||||

| -10 | 0 – 100% Vol. | |||||||||||

| Resolution | 1% LEL | 20 ppm | 1% LEL | 0.1% Vol. | 1 ppm | 1% LEL / 1% Vol. | 20 ppm / 0.01% Vol / 0.1% Vol. / 1% Vol. | |||||

| Lower Detectable Limit (LDL) | 2% of full scale | 0.1% Vol. | 2% of full scale | |||||||||

| Max Current Draw (24VDC) | 160 mA with alarm 1 and alarm 2 active and all relays energized | 125 mA with alarm 1 and alarm 2

active and all relays energized |

160 mA with alarm 1 and alarm 2

active and all relays energized |

|||||||||

| Response Time (T-90) | 35 Seconds or less | 90 Seconds or less |

60 Seconds or less |

90 Seconds or less |

30 Seconds or less | |||||||

| Life Expectancy | 2 to 3 years with normal service | 3 to 5 years with normal service | 2 to 3 years with normal service | 5 years plus with normal service | ||||||||

| Accuracy (which ever is greater) |

± 5% of reading or ± 2% of full scale | ± 0.5% Vol. O2 | ± 5% of reading or ± 2 ppm H2S |

± 5% of reading or ± 5 ppm CO |

± 5% of reading or ± 2 % of full scale | |||||||

| Weather Resistant | Patented water repellent sensor coating | |||||||||||

| Alarms | ||||||||||||

| Alarm Settings | Two fully programmable alarm set points, increasing / decreasing, latching / self-resetting, on delays, off delays, normally energized or de-energized |

|||||||||||

| Alarm Indication | Visual LEDs. Alarm 1, Amber; Alarm 2, Red; Fail, Red | |||||||||||

| Relays | 5 amp form ‘C’ contacts for alarm 1, alarm 2, and fail | |||||||||||

| Physical | ||||||||||||

| Dimensions | Height: 8.5” (215 mm), Width: 5.2” (132 mm), Depth: 4.5” (114 mm) | |||||||||||

| Display | Alphanumeric OLED display. 8 characters per line; 2 lines for gas concentration readout, plus user-friendly calibration and setup |

|||||||||||

| Enclosure | Explosion proof for Class I, Div 1, Groups B, C, D. | |||||||||||

| Enclosure Rating | NEMA 4X, explosion proof, watertight, cast aluminum with o-ring seal and epoxy powder coating | |||||||||||

| Controls | Magnet used for calibration functions. Calibrates without opening the housing. Internal push-button controls also available for calibration and setup |

|||||||||||

| Operating Environment | ||||||||||||

| Operating Temperature | -40°F to 167°F

-40°C to 75°C |

-4°F to 113°F

-20°C to 45°C |

-40°F to 104°F

-40°C to 40°C |

23°F to 104°F

-5°C to 40°C |

-40°F to 122°F

-40°C to 50°C |

|||||||

| Relative Humidity | 5 – 95% RH non-condensing | |||||||||||

| Location | Indoor or outdoor. Explosion proof for Class I, Div. 1, Groups B, C, D. | |||||||||||

| Operating Voltage | 10 VDC – 30 VDC | |||||||||||

| Outputs | ||||||||||||

| Analog | Linear 4-20 mA signal, into 1000 ohms impedance max (24DC), 0 – 500 ohms max (12VDC) corresponding to 0 – full scale | |||||||||||

| Digital | Modbus RTU output standard, fully configurable, 2-wire RS-485, 1200 to 19.2k baud | |||||||||||

| Approvals | 65-2640RK UL |

65-2641RK

UL |

C CSA US | C UL US | ||||||||

| 65-2640RK-05 C CSA US |

65-2641RK-05 C CSA US |

|||||||||||

| Controllers | Beacon 110, Beacon 200, Beacon 410A, Beacon 800 as well as most DCS / PLC systems | |||||||||||

| Warranty | One year material and workmanship | |||||||||||

| O2 Oxygen |

H2S Hydrogen Sulfide |

CO Carbon Monoxide |

Toxics See Chart Below | CO2 Carbon Dioxide |

||||||||

| Part# | 65-2666RK

*65-2644RK |

65-2662RK | 65-2663RK | See Chart Below | 65-2661RK-02

65-2661RK-03 65-2661RK-05 65-2661RK-10 |

|||||||

| Sensors | Galvanic cell | Electrochemical | Infrared | |||||||||

| Measuring Ranges | 0-25% Vol. | 0-100 ppm | 0-300 ppm | See Chart Below | -02 | 0 – 5000 ppm | ||||||

| -03

-05 |

0 – 5% Vol.

0 – 50% Vol. |

|||||||||||

| -10 | 0 – 100% Vol. | |||||||||||

| Resolution | 0.1% Vol. | 1 ppm | See Chart Below | 20 ppm / 0.01% Vol. / 0.1% Vol. / 1%Vol. | ||||||||

| Lower Detectable Limit (LDL) | 0.1% Vol. | 2% of full scale | ||||||||||

| Response Time (T-90) | 35 Seconds or less | 60 Seconds or less | 30 Seconds or less | |||||||||

| Max Current Draw (24VDC) | 125 mA with alarm 1 and alarm 2 active and all relays energized | 160 mA with alarm 1 and alarm 2 active and all relays energized | ||||||||||

| Life Expectancy | 2 to 3 years with normal service | 5 years plus | ||||||||||

| Accuracy (which ever is greater) |

± 0.5% Vol. O2 | ± 5% of reading or ± 2 ppm H2S |

± 5% of reading or ± 5 ppm CO |

± 10% of reading or ± 5% of full scale |

± 5% of reading or ± 2% of full scale |

|||||||

| Alarms | ||||||||||||

| Alarm Settings | Two fully programmable alarm set points, increasing / decreasing, latching / self-resetting, on delays, off delays, normally energized or de-energized, | |||||||||||

| Alarm Indication | Visual LEDs. Alarm 1=Amber; Alarm 2=Red; Fail=Red | |||||||||||

| Relays | 5 Amp form ‘C’ contacts for alarm 1, alarm 2, and fail | |||||||||||

| Physical | ||||||||||||

| Dimensions | Height: 8.5” (215 mm), Width: 5.2” (132 mm), Depth: 4.5” (114 mm) | |||||||||||

| Display | Alphanumeric OLED display. 8 characters per line; 2 lines for gas concentration readout, plus user-friendly calibration and setup | |||||||||||

| Sensor Rating | Non explosion proof construction, designed for Class I, Div. 2, Groups B, C, D (no certification) | |||||||||||

| Housing J-Box | NEMA 4X, explosion proof, watertight, cast aluminum with o-ring seal and epoxy powder coating | |||||||||||

| Controls | Magnet used for calibration functions. Calibrates without opening the housing. Internal push-button controls also available for calibration and setup | |||||||||||

| Sensor | Aluminum / Plastic (non explosion proof) | |||||||||||

| Operating Environment | ||||||||||||

| Operating Temperature | -4°F to 113°F

-20°C to 45°C |

-40°F to 104°F

-40°C to 40°C |

23°F to 104°F

-5°C to 40°C |

14°F to 104°F

-10°C to 40°C |

-40°F to 122°F

-40°C to 50°C |

|||||||

| Relative Humidity | 5 – 95% RH non-condensing | |||||||||||

| Location | Indoor or outdoor | |||||||||||

| Operating Voltage | 10 VDC – 30 VDC | |||||||||||

| Outputs | ||||||||||||

| Analog | Linear 4-20 mA signal, into 1000 ohms impedance max (24DC), 0 – 500 ohms max (12VDC) corresponding to 0 – full scale | |||||||||||

| Digital | Modbus RTU output standard, fully configurable, 2-wire RS-485, 1200 to 19.2k baud | |||||||||||

| Controllers | Beacon 110, Beacon 200, Beacon 410A, Beacon 800 as well as most DCS / PLC systems | |||||||||||

| Warranty | One year materials and workmanship | |||||||||||

|

|

Part Number With J-Box | Gas | Range | Resolution | Sensor Type | |||||||

| 65-2670RK-NH3-75 | Ammonia (NH3) | 0 – 75.0 ppm | 0.1 ppm | CT-7 | ||||||||

| 65-2670-NH3-1 | Ammonia (NH3) | 0 – 100 ppm | 1 ppm | CT-7 | ||||||||

| 65-2670-NH3-2 | Ammonia (NH3) | 0 – 200 ppm | 1 ppm | CT-7 | ||||||||

| 65-2670-NH3-5 | Ammonia (NH3) | 0 – 500 ppm | 1 ppm | CT-7 | ||||||||

| 65-2648RK-AsH3 | Arsine (AsH3) | 0 – 1.50 ppm | 0.1 ppm | ESM -01 | ||||||||

| 65-2670RK-CL2-3 | Chlorine (Cl2) | 0 – 3.00 ppm | 0.01 ppm | CT-7 | ||||||||

| 65-2670RK-CL2-10 | Chlorine (Cl2) | 0 – 10.0 ppm | 0.1 ppm | CT-7 | ||||||||

| 65-2670RK-CLO2 | Chlorine Dioxide (ClO2) | 0 – 1.00 ppm | 0.01 ppm | CT-7 | ||||||||

| 65-2648RK-HCN | Hydrogen Cyanide (HCN) | 0 – 15.0 ppm | 0.1 ppm | ESM -01 | ||||||||

| 65-2648RK-PH3 | Phosphine (PH3) | 0 – 1.00 ppm | 0.01 ppm | ESM -01 | ||||||||

| 65-2648RK-SO2 | Sulfur Dioxide (SO2) | 0 – 6.00 ppm | 0.01 ppm | ESM -01 | ||||||||

| Style | LEL – H2 Specific, Hydrogen Sulfide (H2S), Hydrocarbons (HC), LEL, Oxygen (O2), Carbon Monoxide (CO), CH4 (0-100% Vol.), CH4 (0-100% LEL), CO2 (0-5.0% Vol.), CO2 (0-50% Vol.), CO2 (0-100% Vol.), CO2 (0-5000 ppm) |

|---|

Professional packing and fast shipping

Because of our long-standing partnership in a long-standing partnership with UPS, FedEx, DHL and many other top global carriers we can offer a variety of shipping options. Our warehouse personnel will pack each item according to our strict specifications. Before shipping your items will be thoroughly examined and secured. We deliver to thousands of clients each day across multiple countries. This is a testament to our dedication to being the largest online retailer worldwide. We have distribution centers and warehouses in Europe and in the USA.

Note: Orders containing more than one item will be assigned a different processing period for each item.

Before shipping before shipping, we'll conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48 hours. Delivery is expected to take between three and seven days.

Returns

Due to multiple parties which include the factory as well as the warehouse, we are unable to completely manage our stock. The actual inventory can change at any moment. Be aware that it is possible for your order to run out of stock even after you have made the order.

Our policy lasts thirty days. However, if the 30 days have elapsed from the date you purchased the item, we cannot give you a refund or exchange.

The item you purchase must be in its original packaging and not be used. The item must be in its original packaging.

Related products

FIRE RETARDANT PANTS

LAPCO FR Comfort Flex Jeans | 11oz. Cotton Blend | Big&Tall Lapco

Uncategorized

Beacon 200 Two Channel Wall Mount Controller by RKI Instruments Russmill Bahamas Limited

Uncategorized

Beacon 110 Single Channel Wall Mount Controller by RKI Instruments Russmill Bahamas Limited

FIRE RETARDANT PANTS

FR Modern Carpenter Jeans | 10oz. 100% Cotton Denim | Big & Tall Lapco

FIRE RETARDANT PANTS

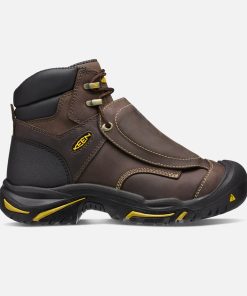

FOOTWEAR ACCESSORIES

FIRE RETARDANT SHIRT

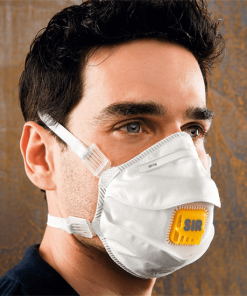

Respiratory Protection

HIGH-EFFICIENCY DISPOSABLE RESPIRATOR FFP3 NR W/VALVE [5pcs] SIR SAFETY SYSTEMS

FIRE RETARDANT PANTS

FIRE RETARDANT SHIRT

IQ Series® Endurance Collection Men’s Fr LB Work Shirt Bulwark Protection