Callington S-WELD BRITE WASH – STAINLESS STEEL & CARBON STEEL CLEANER & CORROSION REMOVER Callington

$ 87,50 $ 43,75

DESCRIPTION

Callington Haven S-Weld Brite Wash is an acidic, biodegradable detergent designed for surface cleaning of stainless steel & carbon steel after fabrication and for in-situ cleaning of architectural stainless steel surfaces.

S-Weld Brite Wash will remove surface dust, soil, rust, rust and water stains, iron and organic contamination without affecting the surface finish of the stainless steel. It can also be used to remove surface corrosion and staining on handrails and other stainless steel surfaces. It is excellent for cleaning of machined carbon steel parts.

CHARACTERISTICS

Callington Haven S-Weld Brite Wash is :

– readily miscible with water

– effectively removes organic soil, dirt and iron

– leaves a clean surface without affecting surface finish – removes corrosion products (rust), rust stain, oxides – aids surface passivation

DIRECTIONS FOR USE

-

General Surface Cleaning After Fabrication

Mix 1 part of Callington Haven S-Weld Brite Wash with 5 to 8 parts of water at room temperature. Spray onto surface by acid resistant spray pump. Some brushing of the surface will assist with removal of corrosion and difficult soils. The surface should be kept wet with the solution until the soil is gone. Rinse the surface; warm water is preferred.

-

Corrosion Removal

Where the surface of handrails, stainless steel cladding or process plant and carbon steel

equipment shows visible signs of corrosion (rusting), S-Weld Brite Wash can be applied by:

Hand Wipe Application

Mix 1 part of S-Weld Brite Wash with 1 part of clean water. Wet surface with a sponge or rag and follow immediately by scrubbing with a stainless steel Scotch Brite type pad. Rinse with clean water once all traces of corrosion are removed.

Spray Application

Mix one part of S-Weld Brite Wash with 1 to 2 parts of clean water. Spray onto surface with an acid resistant spray pump. Where appropriate, scrub the surface with a Scotch Brite pad. For hard to use areas, use a high pressure spray containing a 10% solution of S-Weld Brite Wash.

Rinse thoroughly with clean water when all visible traces of corrosion have been removed.

NOTES

1. If all traces of free iron on stainless surface are specified to be removed, follow up with a 2 to 4 hour treatment using

Callington Haven S-Weld Passivator passivating agent. S-Weld Passivator will generate a stronger and more resilient chrome oxide passive film to corrosion.

2. During stainless steel fabrication, all sandblasted and ground surfaces should be thoroughly cleaned using S-Weld Brite Wash to ensure removal of iron particles and dust.

CAUTION

S-Weld Brite Wash contains Phosphoric Acid.

Avoid contact with skin and eyes, and avoid prolonged breathing of vapour.

Protective gloves, goggles etc are recommended to be worn when handling this product. Use with adequate ventilation.

PACKAGING

S-Weld Brite Wash is available in 5 litre, 20 litre or 200 litre drum. Also available in a 500ml ready to use trigger pack at a pre-dilution of 1:1 with water.

OTHER CALLINGTON HAVEN METAL TREATMENT PRODUCTS:

S-Weld Clean

S-Weld Passivator S-Weld Spatter Guard S-W eld Neutraliser

– Pickling paste

– Passivating gel

– Anti-spatter spray

– Neutralising solution for acidic pickling paste

| Size | Single 5L, 5L Case of 4 |

|---|

Professional packing and fast shipping

Because of our long-standing partnership in a long-standing partnership with UPS, FedEx, DHL and many other top global carriers we can offer a variety of shipping options. Our warehouse personnel will pack each item according to our strict specifications. Before shipping your items will be thoroughly examined and secured. We deliver to thousands of clients each day across multiple countries. This is a testament to our dedication to being the largest online retailer worldwide. We have distribution centers and warehouses in Europe and in the USA.

Note: Orders containing more than one item will be assigned a different processing period for each item.

Before shipping before shipping, we'll conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48 hours. Delivery is expected to take between three and seven days.

Returns

Due to multiple parties which include the factory as well as the warehouse, we are unable to completely manage our stock. The actual inventory can change at any moment. Be aware that it is possible for your order to run out of stock even after you have made the order.

Our policy lasts thirty days. However, if the 30 days have elapsed from the date you purchased the item, we cannot give you a refund or exchange.

The item you purchase must be in its original packaging and not be used. The item must be in its original packaging.

Related products

Disinfectant Cleaner

Callington – Netbiokem DSAM+ Hospital Grade Disinfectant Cleaner 16oz (500mL) Callington

Surface Treatment

Callington – S-Weld Passivator Gel: Thickened Passivator Gel for Stainless Steel Callington

Protective Clothing

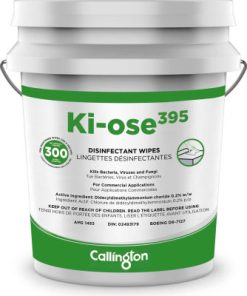

Disinfectant Wipes

Callington Ki-ose 395 Wipes – Surface Disinfectant Wipes Callington

Welding Helmet

Welding Helmet

Hand Sanitizer

WELDING PROTECTION

Welding Accessories

Neutraliser

Callington S-WELD NEUTRALISER – Neutralising Solution for Acidic Pickling Paste Callington

Welding Lens

Disinfectant Cleaner

Callington Aircraft Interior Cleaner – High Performance Disinfectant Cleaner 32 oz Callington

Spray Pickling Solution

Callington S-WELD SPS SPRAY – Spray Pickling Solution, 10L Callington

WELDING PROTECTION

CHICAGO ELECTRIC WELDING – Fixed Shade Welding Helmet Harbor Freight

Welding Helmet

WELDING PROTECTION

Acidic Detergent

Callington ALBRIGHT – Aluminium Brightener & Cleaner Callington

Protective Clothing